+880 1817 64 37 48 / +880 1726 62 66 54 | arhameng2020@gmail.com

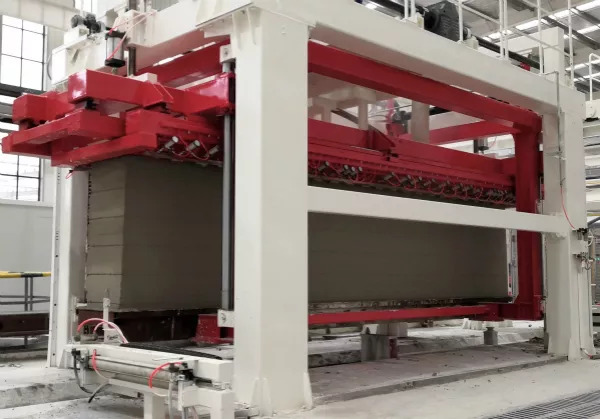

AAC Block Project

AAC blocks are a precast, foam concrete, sustainable construction material made from aggregates of quartz sand, calcined gypsum, lime, Portland cement, water and aluminum powder. After mixing and molding, the concrete is autoclaved under heat and pressure and it thus gains its distinctive properties. AAC bricks are in high demand, owing to their high strength, load-bearing and thermal insulation properties.

Advantages of Autoclaved Aerated Concrete (AAC) Blocks:

1.Faster construction

The blocks are larger in size which makes it easier to movement and leads to faster completion times. AAC Blocks are easier to handle than other blocks. The blocks can easily cut through to make required size & shape and can be easily fit any part of the wall.

2. Moisture-proof

Moisture can severely damage a structure. The macro-pores inside AAC blocks ensure low absorption of water. Thus, they provide better moisture protection and protect the wall from dampness.

3. EARTHQUAKE RESISTANT

The manufacturing process gives the blocks commendable strength, maintaining its light weight property due to which the steadiness of these blocks in buildings is more reliable, making it earthquake resistant.

4. Fire-resistant

The AAC block material is non-combustible and provides fire resistance of up to six hours, depending on the block thickness and up to 1,200 degrees Celsius, compared to other building materials. Thus, it also has importance from a fire safety point of view.

5. Soundproof

The lightweight and porous structure of AAC blocks enables high sound reduction. For this reason, the AAC block material is widely used in the construction of studios, hotels, hospitals, etc.

6. Thermal insulation and energy-efficient

The material contains small air pockets and hydrogen is used to foam the concrete, thus, giving it an excellent heat insulation property that allows temperatures to be warm in winters and cool in summers. Therefore, it can significantly lower your air-conditioning costs by 25%. AAC blocks are energy-efficient across their lifecycle, as their production involves less energy consumption.

7. High compressive strength

The average compressive strength of the AAC block is 3 to 5 N/mm2. Thus, it is much stronger and better than bricks of the same density.

8. Pest-resistant

AAC blocks are prepared from inorganic materials, which help in protecting the structure from pests such as termites, rodents, etc.

9. Sustainable and affordable

AAC blocks are made from natural and non-toxic raw materials and their manufacturing process generates minimum waste. Some of the waste or offcuts generated can be recycled or used in aggregates. As it is made from non-biodegradable materials, it makes the building durable and stable, preventing rot or mold. Furthermore, being lightweight, energy-efficient and easy to install, AAC blocks also minimise labour costs.

10. Saves Money in Building Construction:

Autoclaved aerated concrete blocks can be used with less steel and concrete to hold them in place due to weighing significantly less than traditional concrete blocks. This can lower the cost to construction because you don’t have to use as much of the concrete and steel.